Going to share a quick thought that caught my attention recently. I’m sharing all the time how games and simulations could be an effective first step towards unlearning something, which opens the door for learning something new. So this idea is not new at all. That’s how an exhaustively long list of Kanban games and simulations was created. It was not a new idea that playing towards different goals with different groups and then sharing designs of the systems, strategies, and dynamics could be very helpful. That was the way to play, let’s say getKanban, in a group for years. Also not really new. Now the part I was thinking about…

From multiple multiple observations over time, I do see groups tasked with one certain goal being distracted a bit by some other (imaginary) goals. They are kind of shy taking their goal to absolute, taking it to an extreme. And I think that is important during simulations. Playing not to lose and playing for a win is different. Ideas/dynamics are very different. Experience is also very different. While you are not likely will do 100% the same in real life – but stop!? That’s why we use simulations, right? Sure we won’t do that in real life. We learn through our experience in a simulation to make better management decisions in real life. So that’s always the case, right..? But going through simulation when you are playing to the extreme brings you very different experiences and highlights some of the important dynamics so that you can understand the system better and the effects of your actions better as well.

Let me illustrate this a bit with an open simulation Kanbanboardgame.com, so that you can try this by yourself. One of the typical goals of the simulation could be to “Minimize lead time” (run work elements through the system as quickly as possible). Considering the game design, the potential minimum is 3 days (1 day for analysis + 1 day of development + 1 day of testing). Below you can see the result, which if/when I see as a result from a group in a class like Kanban System Design, I would consider a success.

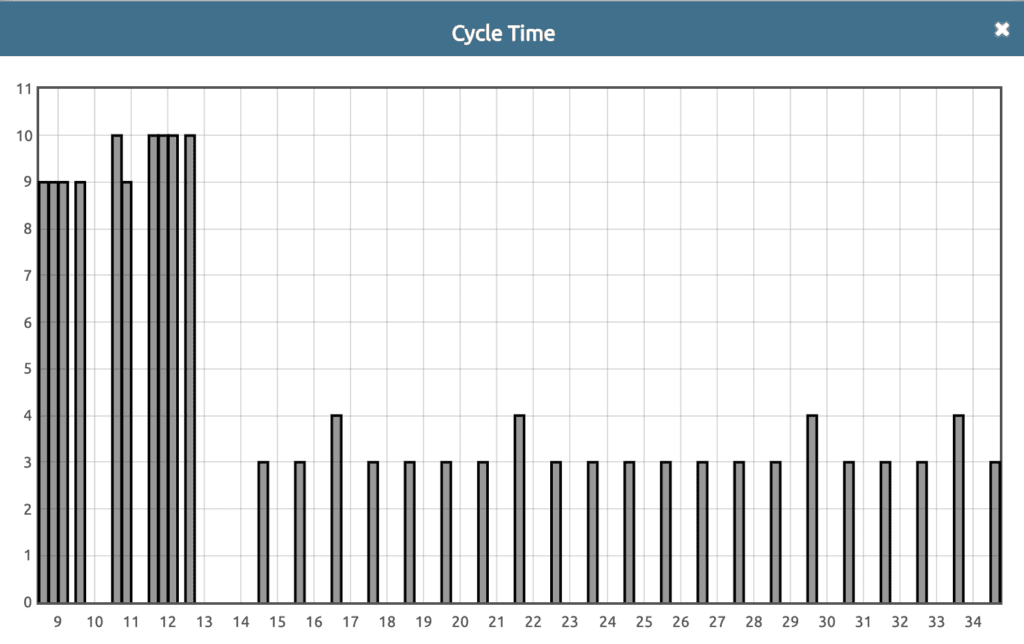

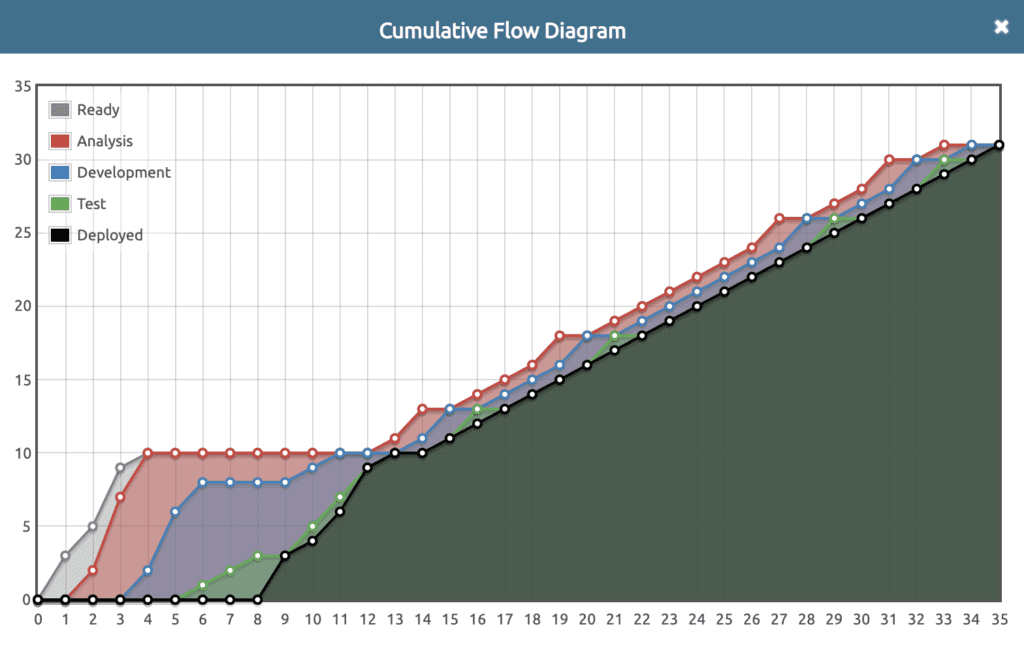

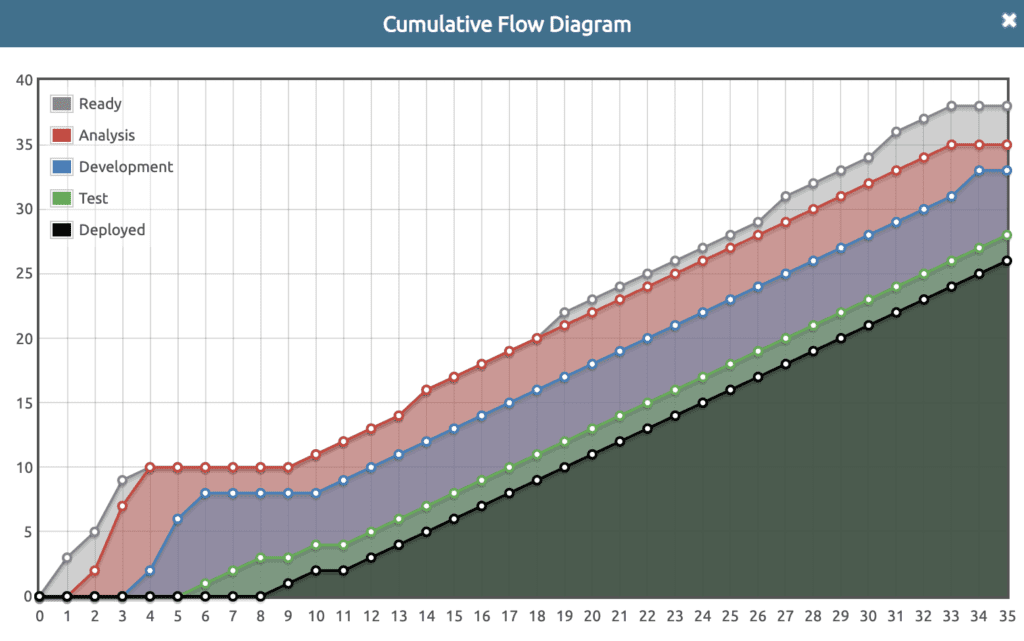

This is a run chart and Cumulative Flow Diagram from the simulation itself:

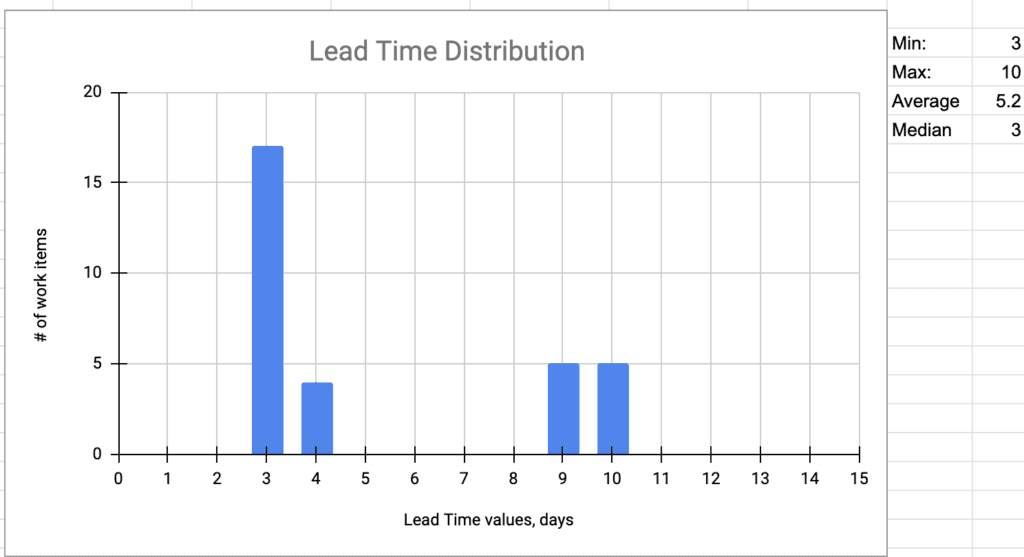

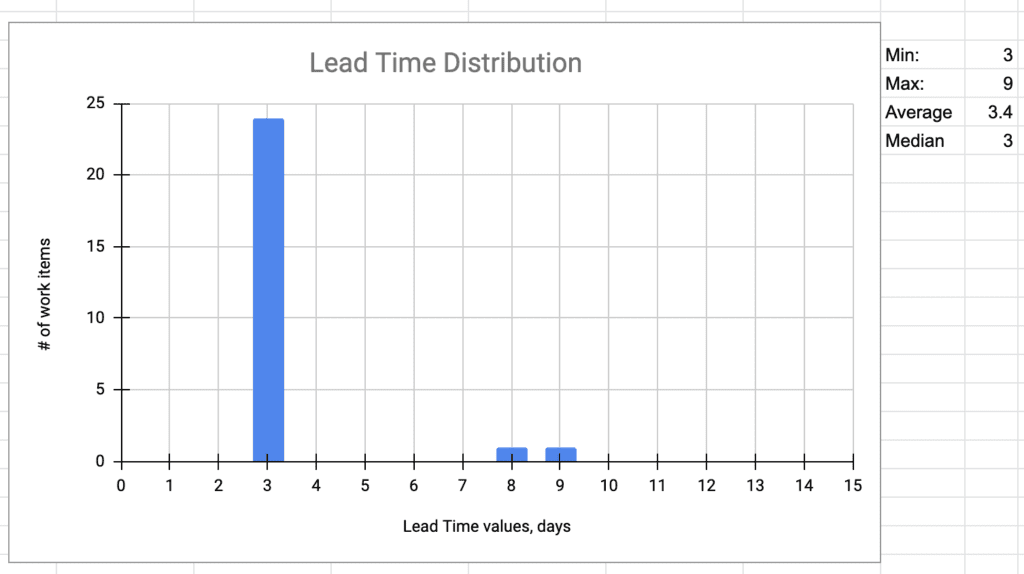

and corresponding Lead Time Distribution with some parameters:

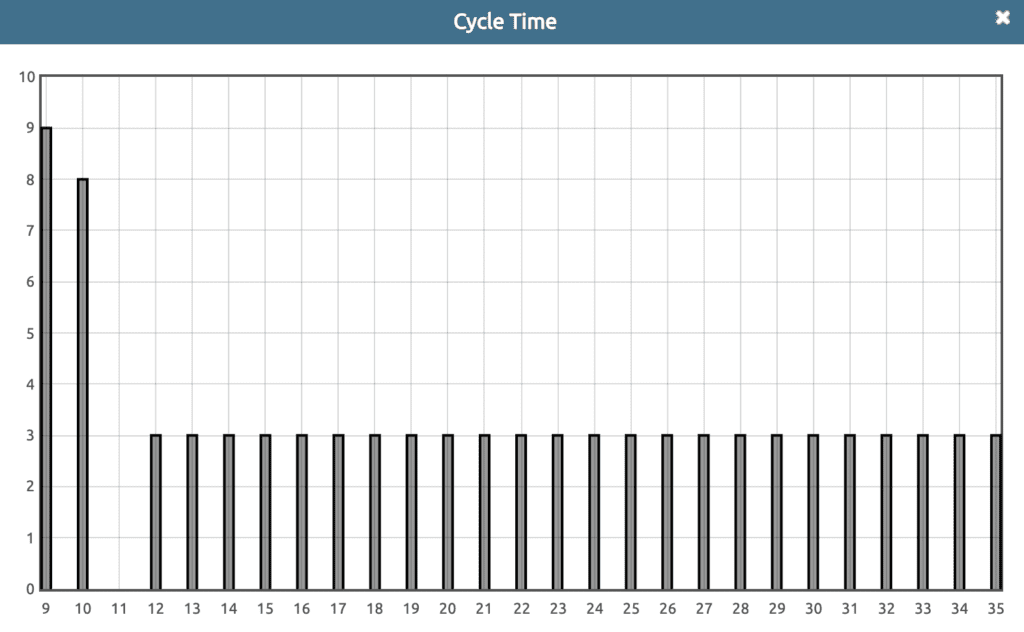

Again, when discussing with the group, I would consider this a success (it could be a bit better because of lack, but the strategy is fine). And this is playing small. This is not taking the goal to an extreme. Here is how it may look:

and corresponding Lead Time Distribution with some parameters:

So, as you can see, this one is way better (average fall down from 5.2 to 3.4). This was achieved for obvious reasons, nevertheless one could hardly argue that formally 2nd one is way better at achieving the goal of minimal lead time…

The experience of playing with these two modes is very different. Going extreme could be very valuable for educational purposes. Good luck with your simulations!